Thursday 31 March 2016

What is the full meaning of DPDT

What is the full meaning of DPST

What is the full meaning of spdt

What is the full meaning of spst

What is the full meaning of SPST

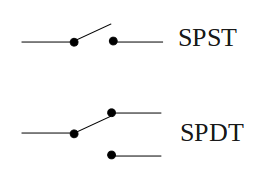

SPST

Single Pole Single Throw. These have two terminals which can be connected or

disconnected. Including two for the coil, such a relay has four terminals in

total. It is ambiguous whether the pole is normally open or normally closed.

The terminology "SPNO" and "SPNC" is sometimes used to

resolve the ambiguity.

Wednesday 30 March 2016

Explain relay

Explain relay

Relay

A relay is an electrically operated switch. Many relays use

an electromagnet to mechanically operate a switch, but other operating

principles are also used, such as solid-state relays. Relays are used where it

is necessary to control a circuit by a low-power signal (with complete

electrical isolation between control and controlled circuits), or where several

circuits must be controlled by one signal. The first relays were used in long

distance telegraph circuits as amplifiers: they repeated the signal coming in

from one circuit and re-transmitted it on another circuit. Relays were used

extensively in telephone exchanges and early computers to perform logical

operations.

A type of relay that can handle the high power required to

directly control an electric motor or other loads is called a contactor.

Solid-state relays control power circuits with no moving parts, instead using a

semiconductor device to perform switching. Relays with calibrated operating

characteristics and sometimes multiple operating coils are used to protect

electrical circuits from overload or faults; in modern electric power systems

these functions are performed by digital instruments still called

"protective relays".

Magnetic latching relays require one pulse of coil power to

move their contacts in one direction, and another, redirected pulse to move

them back. Repeated pulses from the same input have no effect. Magnetic

latching relays are useful in applications where interrupted power should not

be able to transition the contacts.

Magnetic latching relays can have either single or dual

coils. On a single coil device, the relay will operate in one direction when

power is applied with one polarity, and will reset when the polarity is

reversed. On a dual coil device, when polarized voltage is applied to the reset

coil the contacts will transition. AC controlled magnetic latch relays have

single coils that employ steering diodes to differentiate between operate and

reset commands.

Symbol .

Basic design and operation

A simple electromagnetic

relay consists of a coil of wire wrapped around a soft iron core, an iron yoke

which provides a low reluctance path for magnetic flux, a movable iron

armature, and one or more sets of contacts (there are two[clarification needed

: sets or contacts?] in the relay pictured). The armature is hinged to the yoke

and mechanically linked to one or more sets of moving contacts. It is held in

place by a spring so that when the relay is de-energized there is an air gap in

the magnetic circuit. In this condition, one of the two sets of contacts in the

relay pictured is closed, and the other set is open. Other relays may have more

or fewer sets of contacts depending on their function. The relay in the picture

also has a wire connecting the armature to the yoke. This ensures continuity of

the circuit between the moving contacts on the armature, and the circuit track

on the printed circuit board (PCB) via the yoke, which is soldered to the PCB.

When an electric current is passed through the coil it

generates a magnetic field that activates the armature, and the consequent

movement of the movable contact(s) either makes or breaks (depending upon

construction) a connection with a fixed contact. If the set of contacts was

closed when the relay was de-energized, then the movement opens the contacts

and breaks the connection, and vice versa if the contacts were open. When the

current to the coil is switched off, the armature is returned by a force,

approximately half as strong as the magnetic force, to its relaxed position.

Usually this force is provided by a spring, but gravity is also used commonly

in industrial motor starters. Most relays are manufactured to operate quickly.

In a low-voltage application this reduces noise; in a high voltage or current

application it reduces arcing.

When the coil is energized with direct current, a diode is

often placed across the coil to dissipate the energy from the collapsing

magnetic field at deactivation, which would otherwise generate a voltage spike

dangerous to semiconductor circuit components. Such diodes were not widely used

before the application of transistors as relay drivers, but soon became

ubiquitous as early germanium transistors were easily destroyed by this surge.

Some automotive relays include a diode inside the relay case.

If the relay is driving a large, or especially a reactive

load, there may be a similar problem of surge currents around the relay output

contacts. In this case a snubber circuit (a capacitor and resistor in series)

across the contacts may absorb the surge. Suitably rated capacitors and the

associated resistor are sold as a single packaged component for this

commonplace use.

If the coil is designed to be energized with alternating

current (AC), some method is used to split the flux into two out-of-phase

components which add together, increasing the minimum pull on the armature

during the AC cycle. Typically this is done with a small copper "shading

ring" crimped around a portion of the core that creates the delayed,

out-of-phase component,[9] which holds the contacts during the zero crossings

of the control voltage.

protection, Control system, Transformer

definition or explanation of electrical equipment

Explain electrical contactor

Explain electrical contactor

Contactor .

A contactor is an electrically controlled switch used for

switching an electrical power circuit, similar to a relay except with higher

current ratings. A contactor is controlled by a circuit which has a much lower

power level than the switched circuit. Contactors come in many forms with

varying capacities and features.

Parts .

A contactor has

three components. The contacts are the current carrying part of the contactor.

This includes power contacts, auxiliary contacts, and contact springs. The

electromagnet (or "coil") provides the driving force to close the

contacts. The enclosure is a frame housing the contact and the electromagnet.

Enclosures are made of insulating materials like Bakelite, Nylon 6, and

thermosetting plastics to protect and insulate the contacts and to provide some

measure of protection against personnel touching the contacts. Open-frame

contactors may have a further enclosure to protect against dust, oil, explosion

hazards and weather.

Magnetic blowouts use blowout coils to lengthen and move the

electric arc. These are especially useful in DC power circuits. AC arcs have

periods of low current, during which the arc can be extinguished with relative

ease, but DC arcs have continuous high current, so blowing them out requires

the arc to be stretched further than an AC arc of the same current. The

magnetic blowouts in the pictured Albright contactor (which is designed for DC

currents) more than double the current it can break, increasing it from 600 A

to 1,500 A.

Sometimes an economizer circuit is also installed to reduce

the power required to keep a contactor closed; an auxiliary contact reduces

coil current after the contactor closes. A somewhat greater amount of power is

required to initially close a contactor than is required to keep it closed.

Such a circuit can save a substantial amount of power and allow the energized

coil to stay cooler. Economizer circuits are nearly always applied on

direct-current contactor coils and on large alternating current contactor

coils.

A basic contactor will have a coil input (which may be

driven by either an AC or DC supply depending on the contactor design). The

coil may be energized at the same voltage as a motor the contactor is

controlling, or may be separately controlled with a lower coil voltage better

suited to control by programmable controllers and lower-voltage pilot devices.

Certain contactors have series coils connected in the motor circuit; these are

used, for example, for automatic acceleration control, where the next stage of

resistance is not cut out until the motor current has dropped .

Operation .

Unlike

general-purpose relays, contactors are designed to be directly connected to

high-current load devices. Relays tend to be of lower capacity and are usually

designed for both normally closed and normally open applications. Devices

switching more than 15 amperes or in circuits rated more than a few kilowatts

are usually called contactors. Apart from optional auxiliary low current

contacts, contactors are almost exclusively fitted with normally open

("form A") contacts. Unlike relays, contactors are designed with

features to control and suppress the arc produced when interrupting heavy motor

currents.

When current passes through the electromagnet, a magnetic

field is produced, which attracts the moving core of the contactor. The

electromagnet coil draws more current initially, until its inductance increases

when the metal core enters the coil. The moving contact is propelled by the

moving core; the force developed by the electromagnet holds the moving and

fixed contacts together. When the contactor coil is de-energized, gravity or a

spring returns the electromagnet core to its initial position and opens the

contacts.

For contactors energized with alternating current, a small

part of the core is surrounded with a shading coil, which slightly delays the

magnetic flux in the core. The effect is to average out the alternating pull of

the magnetic field and so prevent the core from buzzing at twice line

frequency.

Because arcing and consequent damage occurs just as the

contacts are opening or closing, contactors are designed to open and close very

rapidly; there is often an internal tipping point mechanism to ensure rapid

action.

Rapid closing can, however, lead to increase contact bounce

which causes additional unwanted open-close cycles. One solution is to have

bifurcated contacts to minimize contact bounce; two contacts designed to close

simultaneously, but bounce at different times so the circuit will not be

briefly disconnected and cause an arc.

A slight variant has multiple contacts designed to engage in

rapid succession. The first to make contact and last to break will experience

the greatest contact wear and will form a high-resistance connection that would

cause excessive heating inside the contactor. However, in doing so, it will

protect the primary contact from arcing, so a low contact resistance will be

established a millisecond later.

protection, Control system, Transformer

definition or explanation of electrical equipment

Wednesday 23 March 2016

What is the full meaning of SF6 breaker

What is the full meaning of SF6 breaker

SF6 circuit breaker - sulphur hexafluoride Circuit Breaker

What is the types of circuit breaker

What is the types of circuit breaker

Types of Circuit breaker

1. Low voltage

circuit breaker

2. Medium voltage

circuit breaker

3. High voltage

circuit breaker

1. Low voltage circuit breaker

Low-voltage (less than 1,000 V)

Types .

1. MCB

2. MCCCB

3. ACB

2 . Medium voltage circuit breaker

Medium-voltage

circuit breakers rated between 1 and 72 kV.

Types

Medium-voltage circuit breakers can be

classified by the medium used to extinguish the arc .

1. Vacuum circuit breakers—With rated current up

to 6,300 A, and higher for generator circuit breakers

2. Air circuit breakers—Rated current up to 6,300

A and higher for generator circuit breakers. Trip characteristics are often

fully adjustable including configurable trip thresholds and delays. Usually

electronically controlled, though some models are microprocessor controlled via

an integral electronic trip unit .

3. SF6 circuit breakers extinguish the arc in a

chamber filled with sulphur hexafluoride gas.

3 .High voltage circuit breaker.

The definition of high voltage varies but in power transmission work

is usually thought to be 72.5 kV or higher, according to a recent definition by

the International Electrotechnical Commission (IEC)

Types

1.

Air blast

circuit breaker

2.

Vacuum circuit

breaker

3.

SF6 Circuit

breaker

4.

CO2 Circuit

breaker

define circuit breaker

define circuit breaker

Circuit breaker

protection, Control system, Transformer

definition or explanation of electrical equipment

What is the full meaning of IEC

What is the full meaning of VCB

IEC - International Electrotechnical commission .

The International Electrotechnical Commission is the leading global organization that publishes consensus-based International Standards and manages conformity assessment systems for electric and electronic products, systems and services, collectively known as electrotechnology.

IEC publications serve as a basis for national standardization and as references when drafting international tenders and contracts.

What is the full meaning of VCB

What is the full meaning of VCB

VCB - Vacuum Circuit Breaker .

What is the full meaning of OCB

What is the full meaning of OCB

OCB - Oil Circuit Breaker.

What is the full meaning of ACB

What is the full meaning of ACB

ACB - Air Circuit Breaker

what is the full meaning of RCCB

what is the full meaning of RCCB

RCCB - Residual Current Circuit Breaker.

What is the full meaning of ELCB

What is the full meaning of ELCB

ELCB - Earth Leakage Circuit Breaker.

what is the full meaning of MCCB

what is the full meaning of MCCB

MCCB - Moulded Case Circuit Breaker

what is the full meaning of MCB

what is the full meaning of MCB

MCB - Miniature circuit breaker.

comment your answer.

What is the use of MCB

What is the use of MCB

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overload or short circuit. Its basic function is to detect a fault condition and interrupt current flow

Comment your answer .

protection, Control system, Transformer

definition or explanation of electrical equipment

What are the types of MCB

What are the types of MCB

MCB

Miniature circuit breaker (MCB)—rated

current not more than 100 A. Trip characteristics normally not adjustable

Thermal or thermal-magnetic operation. Breakers illustrated above are in this

category.

There are three main types of MCBs:

- Type

B - trips between 3 and 5 times Instantaneous full load tripping current

2. Type C - trips

between 5 and 10 times Instantaneous full load tripping current

3. Type D - trips

between 10 and 20 times Instantaneous full load tripping current.

Saturday 19 March 2016

What is the differences between ELCB and RCCB

What are the differences between ELCB and RCCB

ELCB - Earth Leakage Circuit Breaker

Characteristics.

- Phase (line), Neutral and Earth wire connected through ELCB.

- ELCB is working based on Earth leakage current.

- Operating Time of ELCB:

- The safest limit of Current which Human Body can withstand is 30ma sec.

- Suppose Human Body Resistance is 500Ω and Voltage to ground is 230 Volt.

- The Body current will be 500/230=460mA.

- Hence ELCB must be operated in 30maSec/460mA = 0.65msec

RCCB - Residual Current Circuit Breaker.

Characteristics.

- Phase (line) and Neutral both wires connected through RCD

- It trips the circuit when there is earth fault current.

- The amount of current flows through the phase (line) should return through neutral

- It detects by RCD. any mismatch between two currents flowing through phase and neutral detect by -RCD and trip the circuit within 30 Millisecond.

- If a house has an earth system connected to an earth rod and not the main incoming cable, then it must have all circuits protected by an RCD (because u mite not be able to get enough fault current to trip a MCB)

- RCDs are an extremely effective form of shock protection

The most widely used are 30 mA (milliamp) and 100 mA devices. A current flow of 30 mA (or 0.03 amps) is sufficiently small that it makes it very difficult to receive a dangerous shock. Even 100 mA is a relatively small figure when compared to the current that may flow in an earth fault without such protection (hundred of amps)

A 300/500 mA RCCB may be used where only fire protection is required. eg., on lighting circuits, where the risk of electric shock is small.

Limitation of RCCB

- Standard electromechanical RCCBs are designed to operate on normal supplywaveforms and cannot be guaranteed to operate where none standard waveforms are generated by loads. The most common is the half wave rectified waveform sometimes called pulsating dc generated by speed control devices, semi conductors, computers and even dimmers.

- Specially modified RCCBs are available which will operate on normal ac and pulsating dc.

- RCDs don’t offer protection against current overloads: RCDs detect an imbalance in the live and neutral currents. A current overload, however large, cannot be detected. It is a frequent cause of problems with novices to replace an MCB in a fuse box with an RCD. This may be done in an attempt to increase shock protection. If a live-neutral fault occurs (a short circuit, or an overload), the RCD won’t trip, and may be damaged. In practice, the main MCB for the premises will probably trip, or the service fuse, so the situation is unlikely to lead to catastrophe; but it may be inconvenient.

- It is now possible to get an MCB and and RCD in a single unit, called an RCBO (see below). Replacing an MCB with an RCBO of the same rating is generally safe.

- Nuisance tripping of RCCB: Sudden changes in electrical load can cause a small, brief current flow to earth, especially in old appliances. RCDs are very sensitive and operate very quickly; they may well trip when the motor of an old freezer switches off. Some equipment is notoriously `leaky’, that is, generate a small, constant current flow to earth. Some types of computer equipment, and large television sets, are widely reported to cause problems.

- RCD will not protect against a socket outlet being wired with its live and neutral terminals the wrong way round.

- RCD will not protect against the overheating that results when conductors are not properly screwed into their terminals.

- RCD will not protect against live-neutral shocks, because the current in the live and neutral is balanced. So if you touch live and neutral conductors at the same time (e.g., both terminals of a light fitting), you may still get a nasty shock.

Difference between ELCB and RCCB

- ELCB is the old name and often refers to voltage operated devices that are no longer available and it is advised you replace them if you find one.

- RCCB or RCD is the new name that specifies current operated (hence the new name to distinguish from voltage operated).

- The new RCCB is best because it will detect any earth fault. The voltage type only detects earth faults that flow back through the main earth wire so this is why they stopped being used.

- The easy way to tell an old voltage operated trip is to look for the main earth wire connected through it.

- RCCB will only have the line and neutral connections.

- ELCB is working based on Earth leakage current. But RCCB is not having sensing or connectivity of Earth, because fundamentally Phase current is equal to the neutral current in single phase. That’s why RCCB can trip when the both currents are deferent and it withstand up to both the currents are same. Both the neutral and phase currents are different that means current is flowing through the Earth.

- Finally both are working for same, but the thing is connectivity is difference.

- RCD does not necessarily require an earth connection itself (it monitors only the live and neutral).In addition it detects current flows to earth even in equipment without an earth of its own.

- This means that an RCD will continue to give shock protection in equipment that has a faulty earth. It is these properties that have made the RCD more popular than its rivals. For example, earth-leakage circuit breakers (ELCBs) were widely used about ten years ago. These devices measured the voltage on the earth conductor; if this voltage was not zero this indicated a current leakage to earth. The problem is that ELCBs need a sound earth connection, as does the equipment it protects. As a result, the use of ELCBs is no longer recommended.

Click here to Watch : How to work earth leakage circuit breaker

What is the difference between MCB and MCCB

What is the difference between MCB and MCCB

MCB - Miniature Circuit Breaker

Singe pole mcb

Two pole MCB

3 Pole MCB

4 pole MCB

Characteristics.

- Rated current not more than 100 A.

- Trip characteristics normally not adjustable.

- Thermal or thermal-magnetic operation.

MCCB - Moulded Case Circuit Breaker

Characteristics.

- Rated current up to 1000 A.

- Trip characteristics often fully adjustable including configurable trip thresholds and delays.

- Usually electronically controlled—some models are microprocessor controlled.

- Often used for main power distribution in large industrial plant, where the breakers are arranged in draw-out enclosures for ease of maintenance.

Subscribe to:

Posts

(

Atom

)